Product Parameter

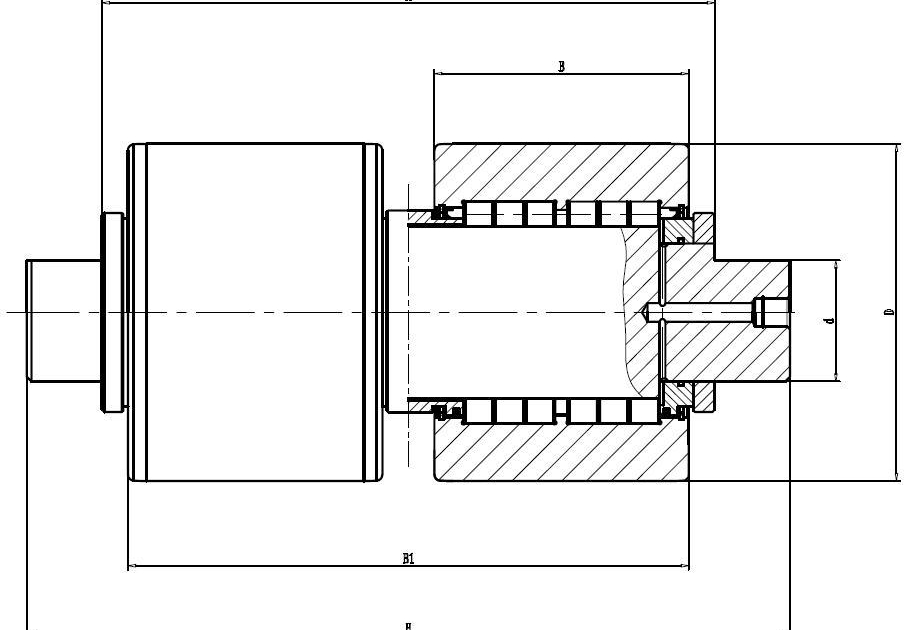

Backup Rollers

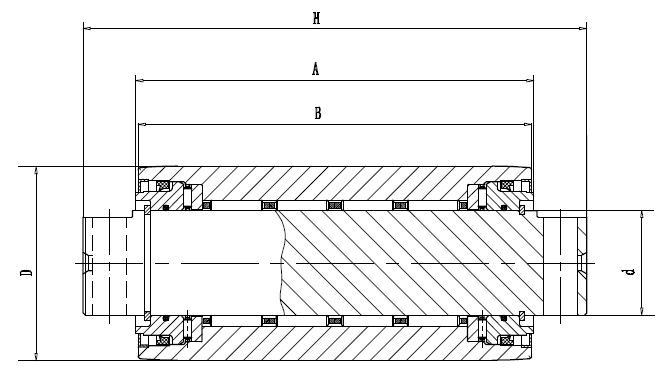

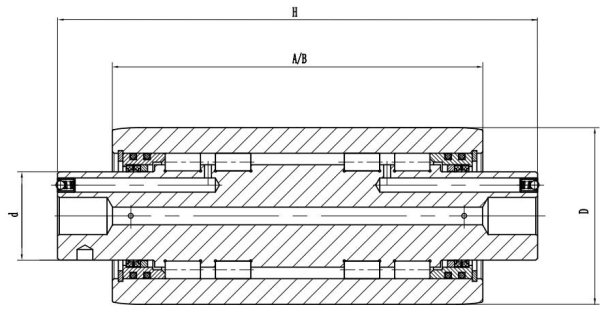

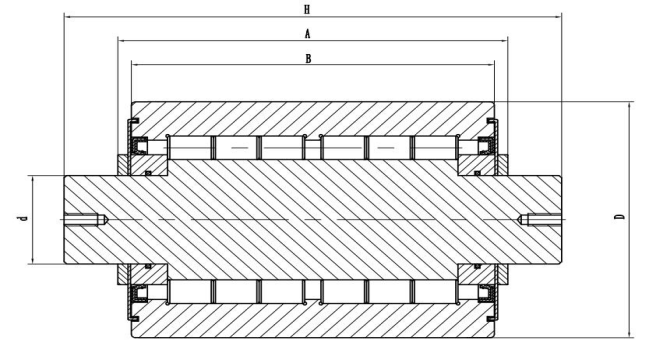

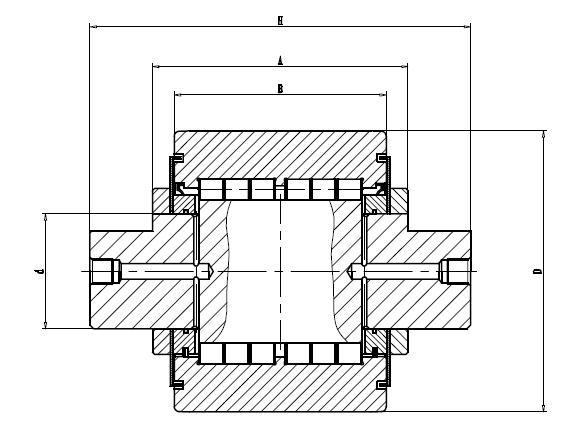

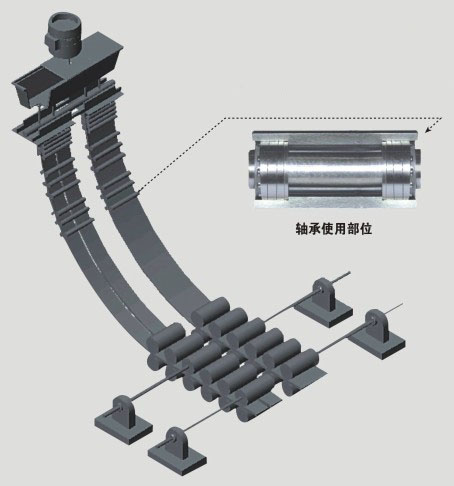

Back-up rollers for tension levelers and metal flattening machines are made in two different styles:

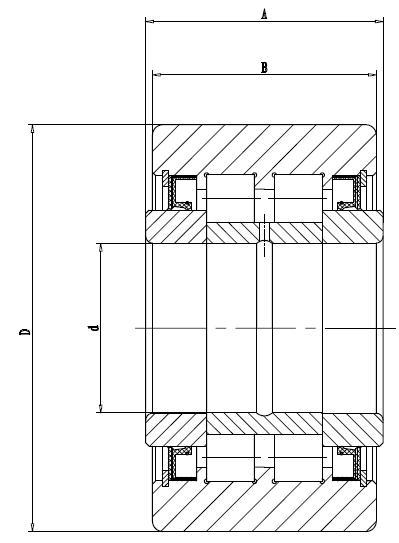

– with full complement of cylindrical rollers

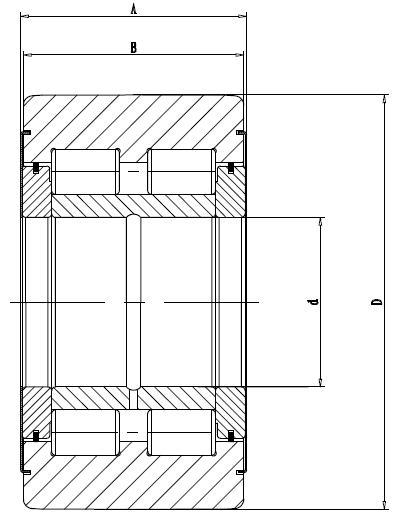

– with roller cages in mould steel or brass.

The full complement style allows the bearing to reach a high load capacity both dynamic and static.

The roller cage style (made of two or more cages), along with the wide working surface, allow for increased flattening performance and high speed. The distance rings on the outer ring and the pivot, plus the circle clearance, which is calculated at the minimum, allow a good support of axial loads. The style with roller cages represents the most advanced series of back-up rollers.

This series of backup rollers is usually manufactured with two lateral thrust bearings in the inner body, either with balls or rollers, which guarantee a very strong support of axial loads.

The backup rolls have a grease lubrication system and are already pre-lubricated. The lubrication system foresees both the entrance and the exit of grease. They can be supplied also in Long-life execution. The sealing system is very efficient, it doesn’t allow any outer agents such as, dust, mill scale, humidity to enter the back-up roll, at the same time, it prevents the leakage of grease.

Precision class is P0, on request the backup rollers can be manufactured with precision class P6 or P5. Special designs can be produced on requests.