Spring bush bearings with phosphatized coating

The spiral ring roller bearings produced by our Company are applicable in the high-temperature working area. When its temperature reaches 300, the bearing can still bear shock vibration load, ensuring the operation accuracy of the equipment.

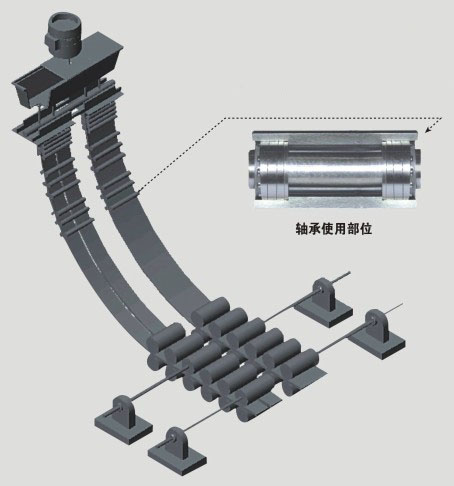

Working conditions of the bearing dedicated to continuous casting machine:

High temperature – thermal radiation temperature in casting blank.

Shock – shock vibration load incurred in jiggering blank.

Dust – metal oxide producing in cooling cast blank.

Waste water – flow and high-temperature steam of cooling water.

Spiral Ring Roller Bearings

The inner/outer rings and rolling elements of these bearings may be fabricated to elastomers according to the working conditions, which accordingly saves space occupation of bearings significantly and facilitates easy assembly/disassembly.

Performance features:

1.The axial stretch of inner/outer ring and rolling element under high-temperature environment enables automatic compensation of radial internal clearance, which tackles the tough task of locking bearing when the rigid bearing encounters narrowed clearance at high temperature.

2.Satisfactory lubrication performance: The proper gap among the components and arrangement mode of rolling elements contribute to the continuous and even distribution of lubricating oil on the working surfaces.

3.Strong impact toughness: The components feature good elastic deformation absorbing shock wave energy sufficiently, which not only maintains stable precision of bearing, but also protects the equipment.