Crane Sheave Bearing SL04170PP, Full Complement Cylindrical Roller Bearing

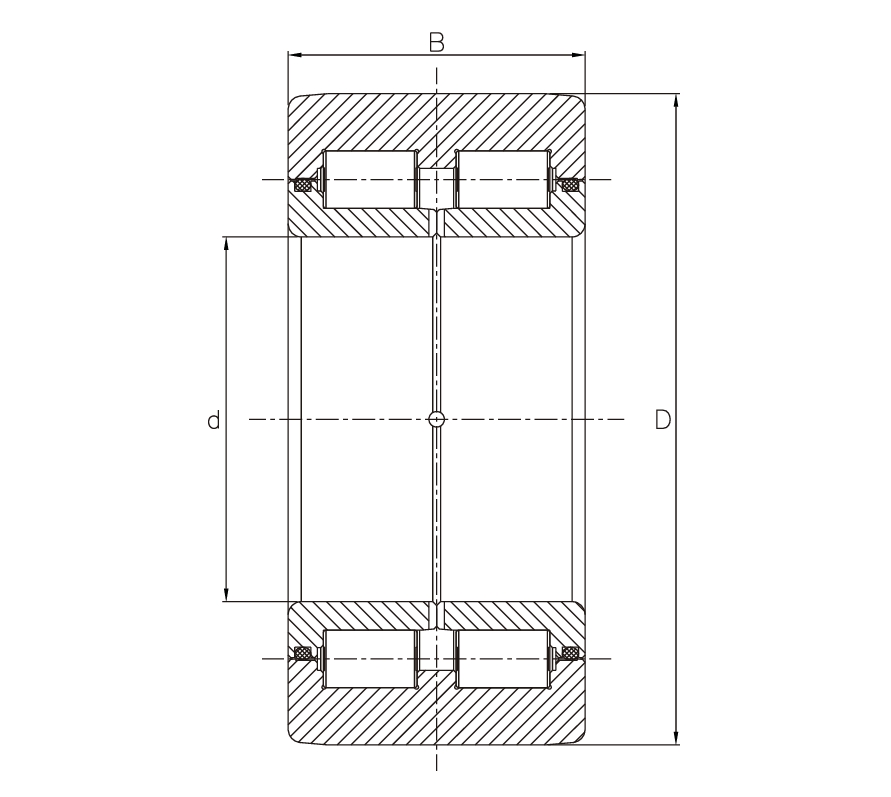

SL04170PP Sheave Bearing 2 Rows Full Complement Bearings with rubber contact seals

ID (inner diameter)/Bore: 170mm

OD (outer diameter): 230mm

Width/Height/thickness: 80mm

Dynamic load rating Cr: 99,500 N

Static load rating Cor: 158,000 N

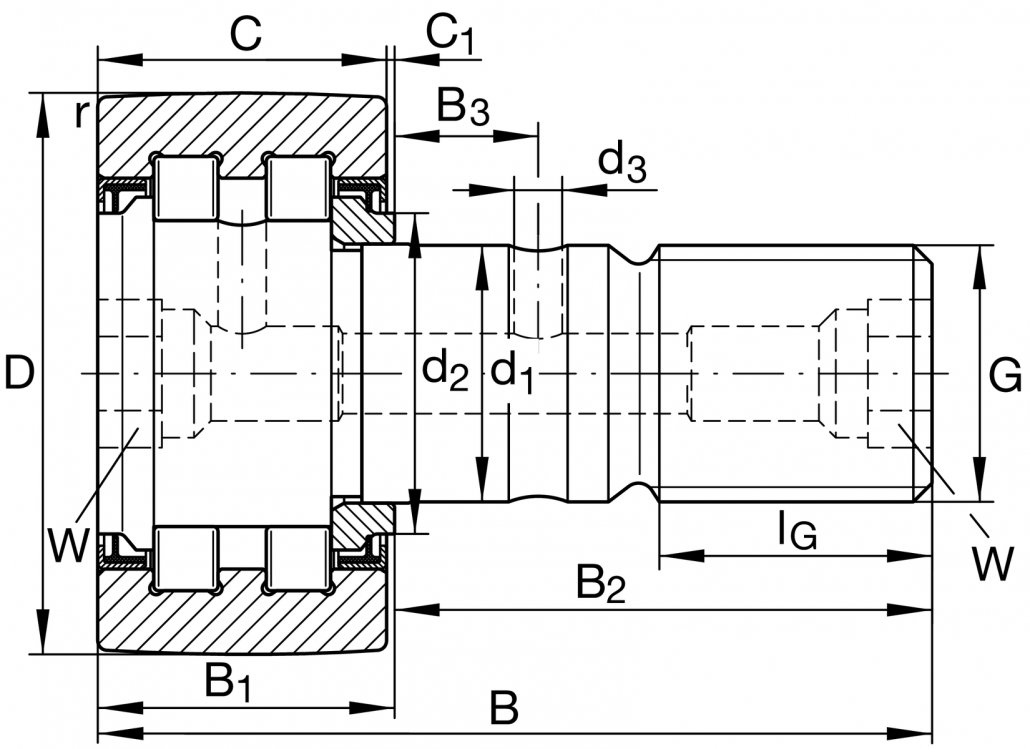

Combined roller bearing 4.063, 4.064 in assembly

Combined bearing 4.063

D=149mm

H=78.5mm

h=58.5mm

d=60mm

T=103mm

Combined bearing 4.064

D=149mm

H=86mm

h=67mm

d=60mm

T=108mm

Full Complement Cylindrical Roller Bearings SL185020 in assembling

Full Complement Cylindrical Roller Bearings SL1850 Series has three integral flanges on the inner ring and one integral flange on the outer ring. This kind of bearing can provide axial location for a shaft in one direction. A snap ring is inserted in the outer ring at the side opposite the integral flange.

SL18 5020 Full Complement Cylindrical Roller Bearing

Inside Diameter (d) 100mm

Outside Diameter (D) 150mm

Width (B) 67mm

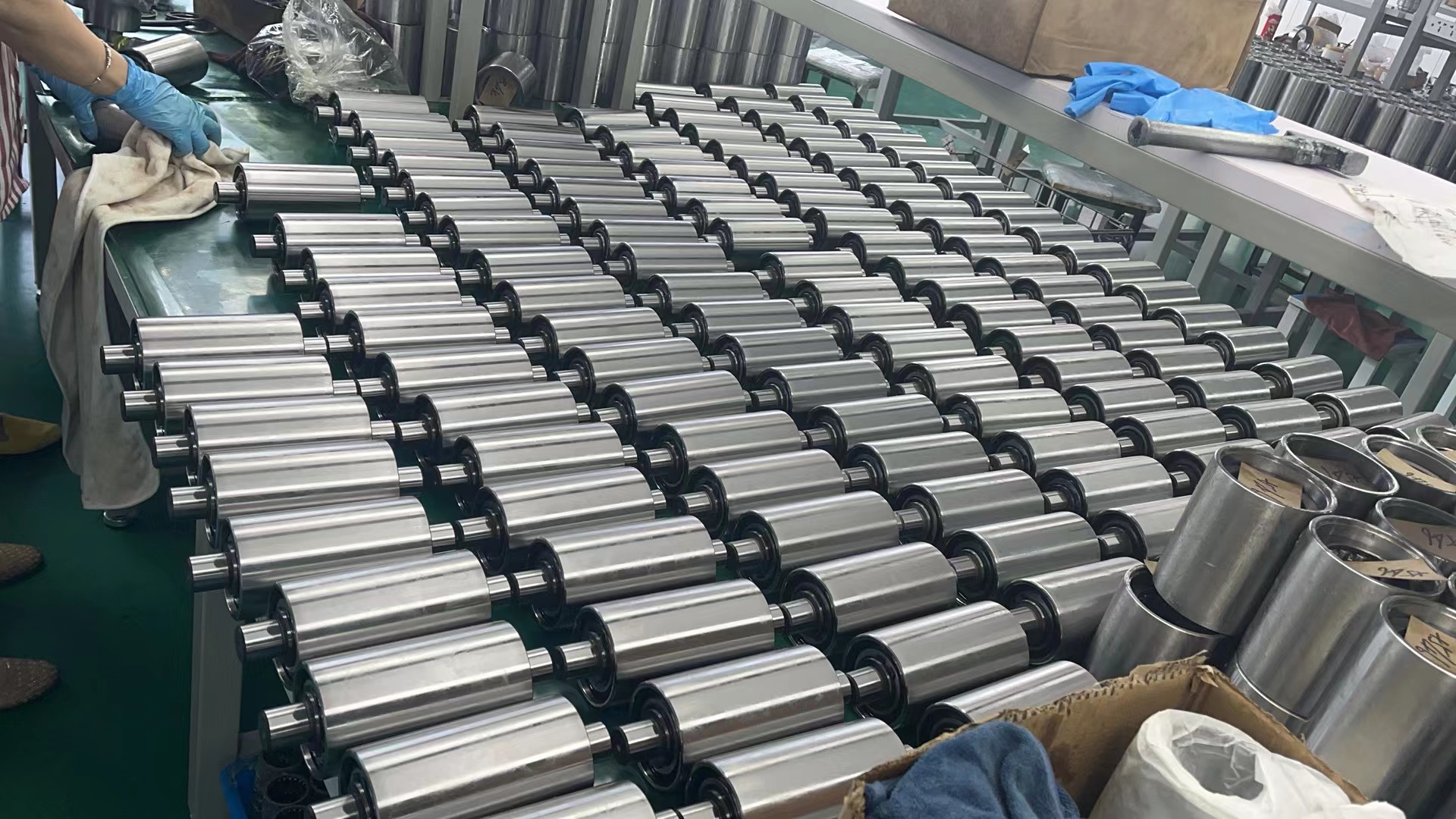

Spring Bush Bearings: A Resilient Solution for Industrial Applications

Introduction

Spring bush bearings, also known as spring roller bearings, find widespread use in various applications. One of the most typical areas of application is the steel industry. These bearings are employed in various components, including:

- Rollers in Steel Mills: In rolling mills, spring bush bearings support the rollers that shape and process steel sheets.

- Continuous Casting Machines: Spring bush bearings are used for supporting the guide rollers and directing rollers in continuous casting machines.

-

Furnace Equipment: Inside furnaces or refining equipment, spring bush bearings are utilized for the rollers that handle hot materials.

Construction and Components

Construction and ComponentsThe construction of spring bush bearings is relatively straightforward. They consist of three main components:

- Inner Ring: The inner ring provides the mounting surface for the bearing.

- Rolling Elements: These typically include cylindrical rollers with a retaining cage. The rolling elements facilitate smooth rotation.

- Outer Ring: The outer ring encloses the entire assembly and provides stability.

These basic elements can be assembled to create various types of bearings, depending on specific requirements. Whether the application involves split bearing housings, high-temperature operations, or axial load transmission, spring bush bearings can adapt. They handle impact loads and minor misalignments with ease, making them versatile even when multiple challenges arise simultaneously. Additionally, these bearings exhibit excellent wear resistance.

Elasticity and Tolerance

One notable feature of spring bush bearings is their inherent elasticity. The slight clearance between the inner and outer rings allows them to maintain functionality even under conditions like bending deformation. This property makes them particularly suitable for continuous casting machines and high-temperature transfer equipment.

Advantages of Spring Bush Bearings

- Robust Design: Spring bush bearings share a similar height profile with needle roller bearings but offer greater durability. They can withstand temperature variations, contamination, and inadequate lubrication.

- Tolerance to Deviations: These bearings tolerate deviations and inclinations, making them ideal for challenging environments.

-

Application Range: Spring bush bearings find applications beyond the steel industry. They are also used in mining, cement, and other heavy-duty sectors.

Backup Rollers for Levelling Lines: Enhancing Precision and Performance

In the intricate world of metal processing, where precision and efficiency are paramount, backup rollers play a crucial role. These unassuming components provide essential support to tension levelers and metal flattening machines, ensuring optimal performance and consistent results.

Types of Backup Rollers

Full Complement Style:

These backup rollers feature a cylindrical design with a full complement of rollers.

Advantages:

High load capacity (both dynamic and static).

Robust support for axial loads.

Grease lubrication system.

Efficient sealing to prevent contamination.

Ideal for applications where load-bearing capacity is critical.

Roller Cage Style:

Constructed with roller cages made of mold steel or brass.

Advantages:

Wide working surface for increased flattening performance.

High-speed operation.

Strong axial load support.

Pre-lubricated and sealed.

Represents an advanced series of backup rollers.

Precision and Customization

Precision Class: Backup rollers are typically manufactured with precision class P0, but precision classes P6 or P5 can be requested.

Custom Designs: Special designs can be produced upon request to meet specific application requirements.

Applications and Beyond

Tension Levelers: Backup rollers ensure stable material processing during tension leveling, preventing work roll deflections.

Metal Flattening Machines: These rollers contribute to consistent sheet flatness and quality.

Spiral Pipe Mills: Forming roller bearings (similar to yoke-type track rollers) are used in spiral pipe mills.

While backup rollers may not grab headlines, their impact on metal processing is undeniable. From maintaining sheet flatness to supporting axial loads, these unheralded heroes keep the industry rolling smoothly. So, next time you admire a perfectly leveled metal sheet, remember the unsung backup rollers that made it possible!

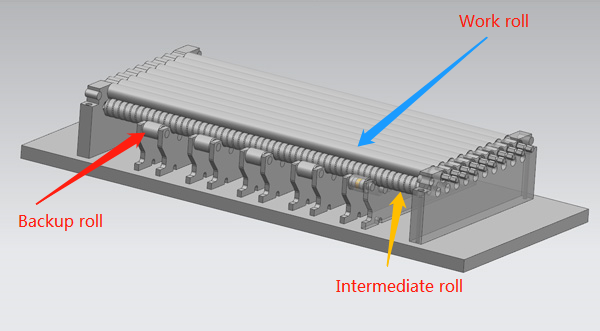

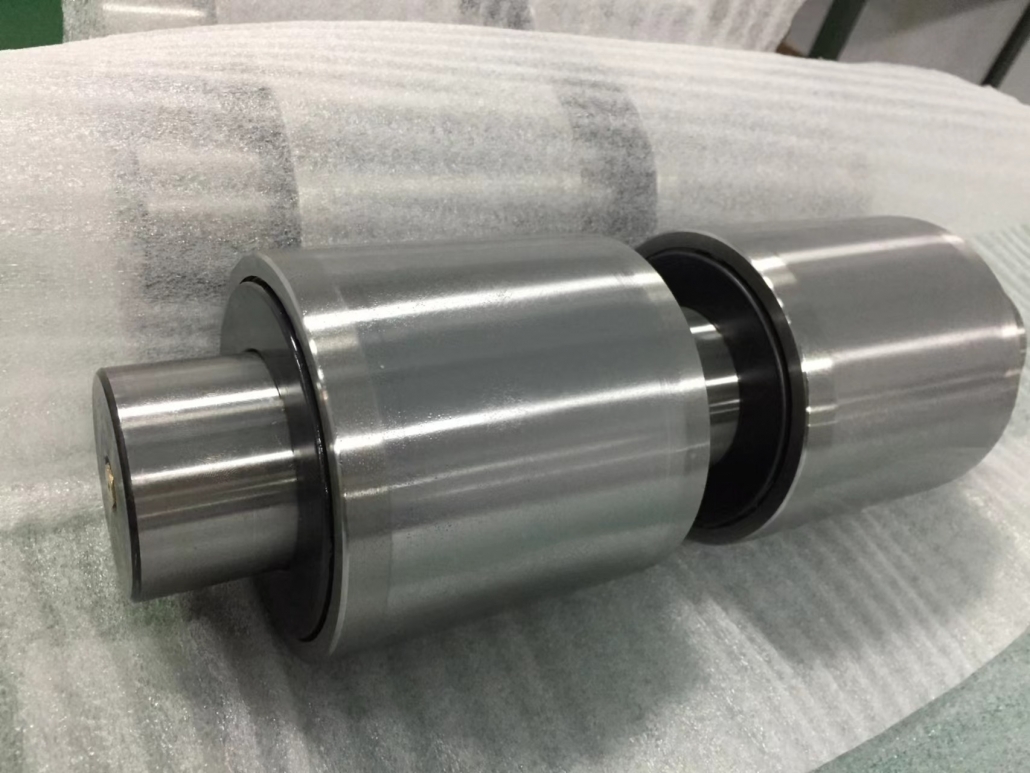

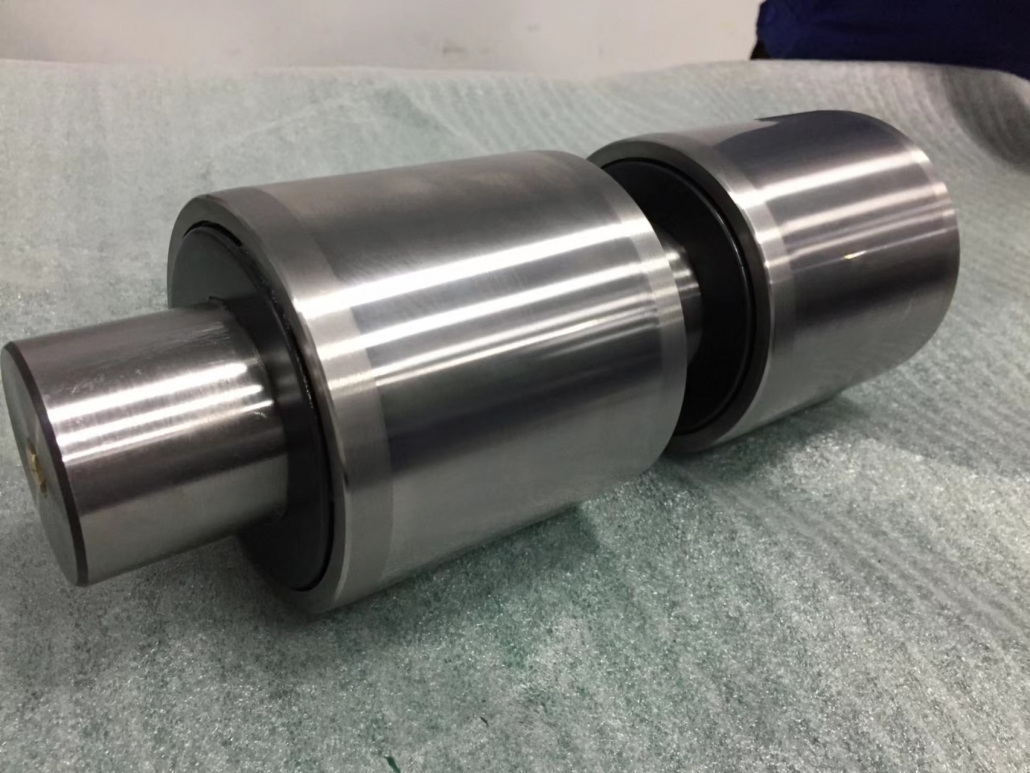

Pressure roller bearing used for pallet cars in sinter plant

The pressure roller bearings are mainly used in the continuous furnaces of sintering plants. They are massive bearings ready to be fixed. They are used with heavy loads and where the rotation reverses continuously at low speed.

The outer ring shows three entire borders, one section and one outer surface which is highly resistant to wear.

The inner ring is made of two parts, each one has an entire border expressly developed in order to bear high axial thrusts, in addition to radial loads.

Pressure roller bearings do not need maintenance.

The outer ring and the inner ring are manufactured in GCr18Mo steel.

Hardness 60-2 HRC.

In order to increase the resistance to wear, pressure roller bearings usually undergo bainitic temper treatment up to 250° C, named S2.

The sealing system foresees the presence of Viton O-rings, which are inserted in the proper grooves on the inner ring. The seals allow the bearing to be disassembled, they prevent the entrance of contaminating agents and in the meantime, the leakage of lubricant.

| Code | d | D | B | Load ratings | |

| C (KN) | Co (KN) | ||||

| PRB88x170x95 | 88 | 170 | 95 | 384 | 908 |

| PRB93x170x95 | 93 | 170 | 95 | 384 | 908 |

| PRB93x171x95 | 93 | 171 | 95 | 384 | 908 |

| PRB110x200x90 | 110 | 200 | 90 | 414 | 841 |

| PRB110x210x110 | 110 | 210 | 110 | 479 | 942 |

| PRB110x300x87/133 | 110 | 300 | 87/133 | 604 | 1022 |

| PRB120x190x130 | 120 | 190 | 130 | 580 | 1570 |

| PRB120x210x113.8 | 120 | 210 | 113.8 | 584 | 1268 |

| PRB120x210x114 | 120 | 210 | 114 | 584 | 1268 |

| PRB128.665x210x101.6 | 128.665 | 210 | 101.6 | 393 | 1132 |

| PRB128.665x210x114 | 128.665 | 210 | 114 | 463 | 1395 |

| PRB130x210x132 | 130 | 210 | 132 | 529 | 1659 |

| PRB130x250x132 | 130 | 250 | 132 | 899 | 1664 |

| PRB140x250x114 | 140 | 250 | 114 | 769 | 1601 |

| PRB140x250x130 | 140 | 250 | 130 | 899 | 1957 |

U profile stud type track roller bearings used for guide rails

The new finished U profile stud type track roller bearings with ball & cage structure, the oil seal design can prevent the contaminants outside.

The bearings can support high radial- and axial forces in both directions. The special curved shape of the outer ring creates two contact surfaces with the guide rail.

With these track roller bearings, carriages will run quickly and quietly on guide rails.

These track rollers are lubricated and maintenance-free during their service-life.

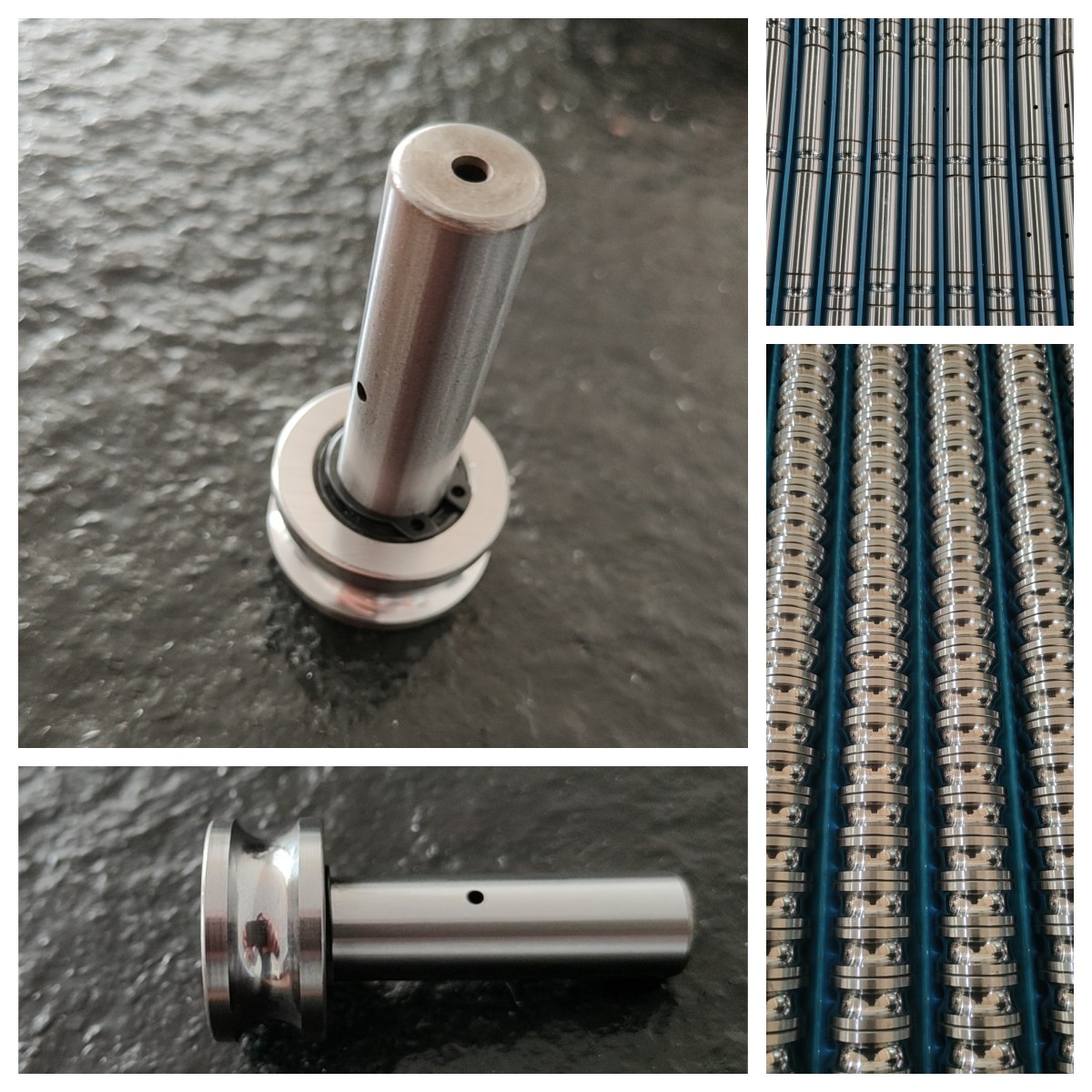

Stud type track roller | Cam follower PWKR80-2RS ready for delivery to our European clients

Stud type track roller | Cam follower PWKR80-2RS

Stud type track rollers PWKR..-2RS, with axial guidance, full complement cylindrical roller set, lip seals on both sides.

The PWKR..-2RS type include PWKR35-2RS, PWKR40-2RS, PWKR47-2RS, PWKR52-2RS, PWKR62-2RS, PWKR72-2RS, PWKR80-2RS, PWKR90-2RS.

Also we can produce special designs and dimensions as the requirements of customer.

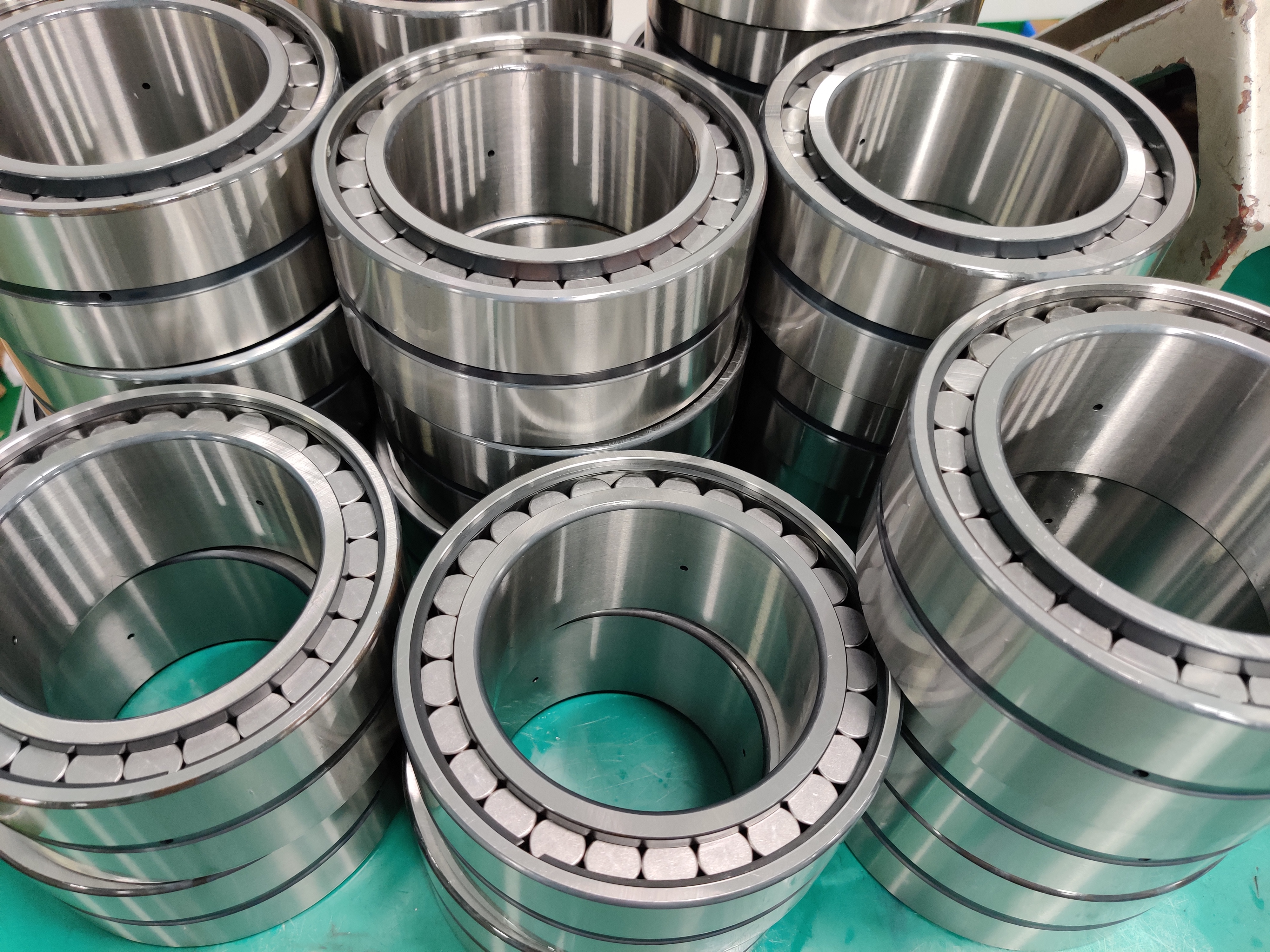

Double roller back-up rollers with pin used for levelling lines

The double roller back-up rollers with pin back-up rolls mainly used in the flattening and straightening lines of steel, stainless steel and aluminium sheets. The outer rings and the shaft are made in hardening and tempering steel with high hardness (up to 62 HRc). The shaft can be made also in case hardening steel in relations to the dimensions. They are available with sealing system (lamellar double or triple rings), thermoplastic seals and labyrinth system.

The internal design with needle roller and cage assembly or full complement rollers, so it can bear very high radial load capacity. The backup rollers work with the work rolls and the intermediate rolls in the levelling lines.