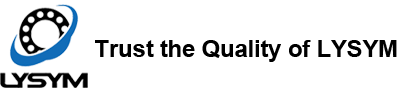

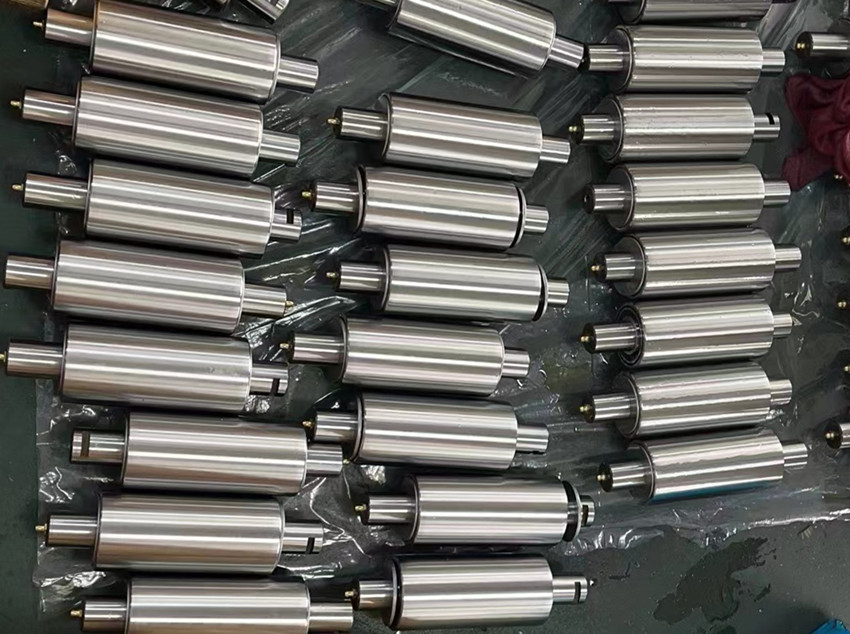

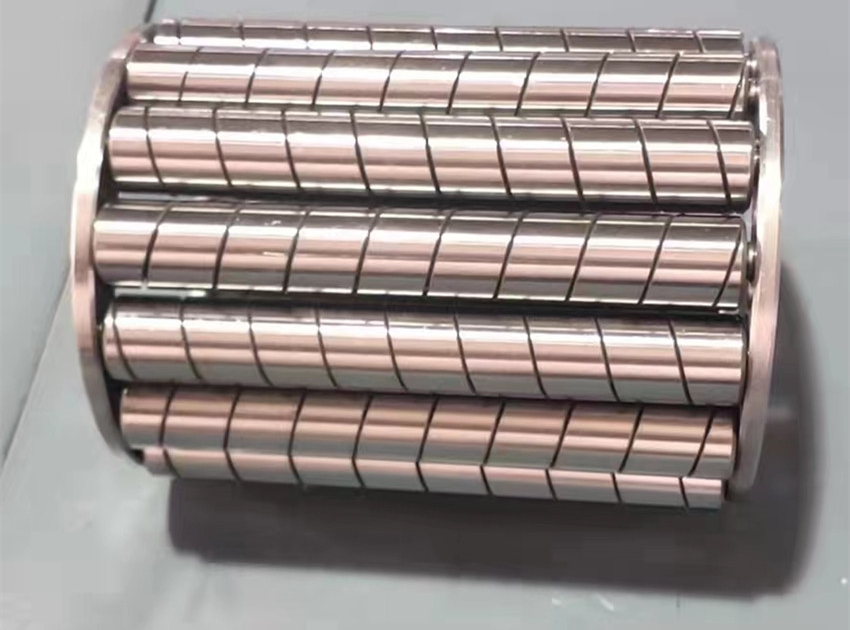

Rolling mill work rolls ready for delivery to our European client

Work rolls are for flat rolling in the steel, aluminium and non-ferrous industries, food industry, natural materials, the rolls are forged, heat treated uniform barrel hardness, excellent wear resistance and grinding & texturing properties.

Description: Work Roll/Intermediate Roll/BackUp Roll for Cold Rolling Mills, Forged Steel Roll for Cold Rolling Mills

Application: Metal Straightening Machinery, Metal Processing Machinery, Cold Rolling Strip Mill

We can customize the roll according to customer’s special requirements.

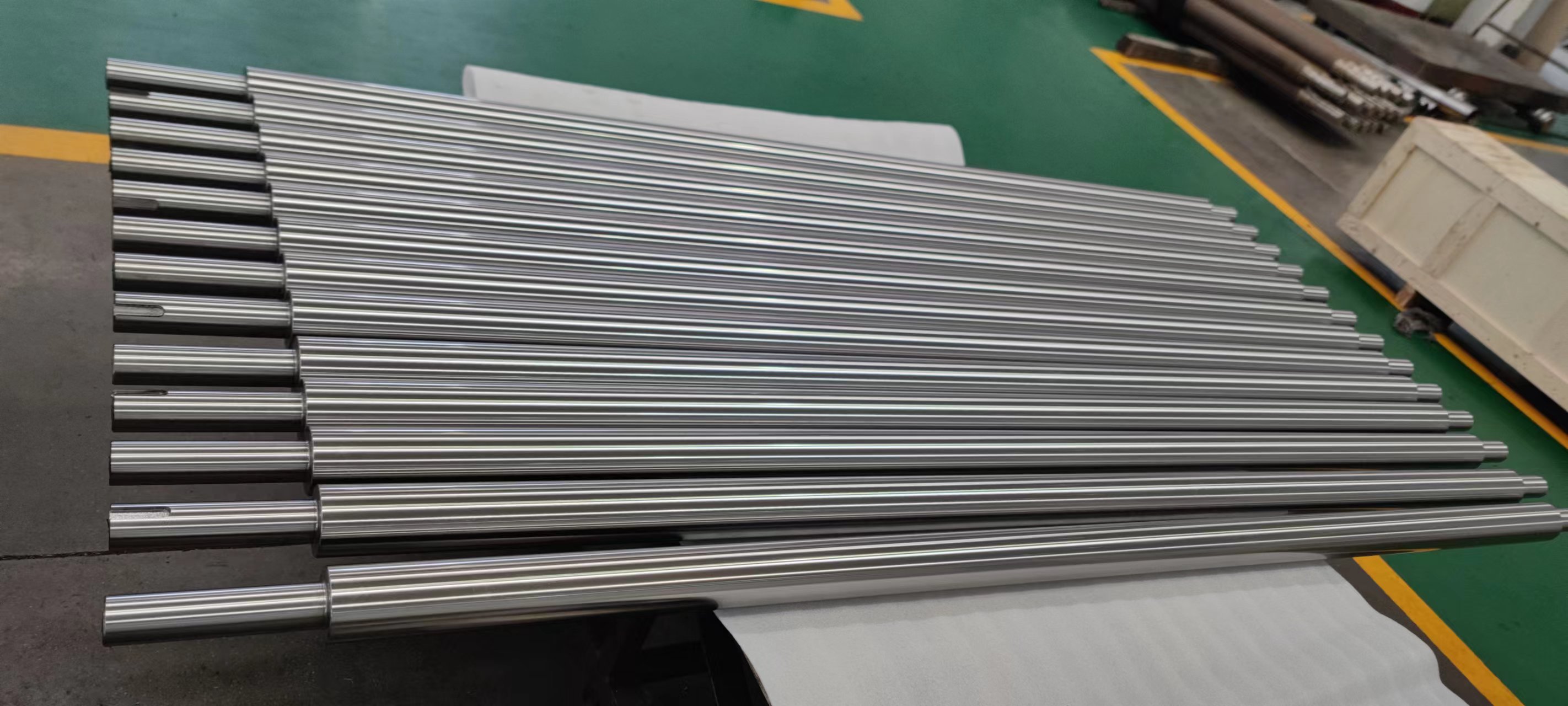

Back up roll BUR46181 used for coil processing lines for our European customer

The cold rolling back up rolls are widely used in the steel industry in various types of straightening equipment in the galvanizing line, tin-plating line, rewinding line, continuous rewinding line, scale breaking line and other process sections for rotational support and load-bearing purposes. The rolls are designed to meet the requirements of different working conditions in terms of structure, load-bearing capacity, precision, wear resistance, starting torque and sealing.

Cold rolling back up roll is widely used in cold rolling leveling equipment. Generally, multiple sets of back up roll are used to support a group of intermediate rolls and work rolls. Therefore, the consistency of the outer diameter and H value of the back up roll is required.

According to different working conditions, the requirements of the back up roll are different. For example, scale breaker is mainly concerned with bearing capacity and sealing. Tinning line is mainly concerned with rotation flexibility and lubrication effect and so on.

The back up rolls/back-up rollers BUR46181 are used for our customer’s coil processing lines leveling machines.

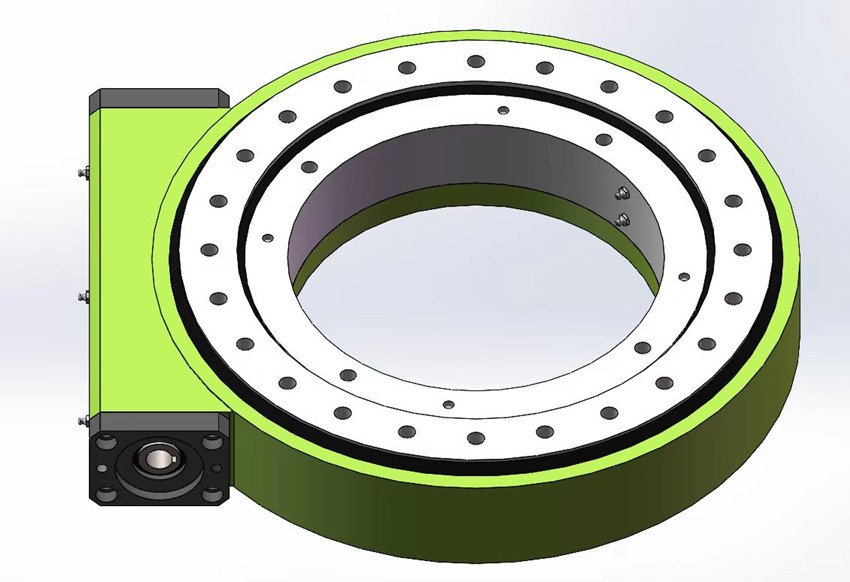

What is a slewing drive and how it works?

The slewing drive is a complete system assembly that can be easily installed and integrated into existing system programs.

It is composed of ball slewing bearing or cylindrical roller slewing bearing, worm, shell and other parts that can bear axial, radial and overturning moments at the same time. The worm is driven by a hydraulic motor or motor to drive the slewing bearing to rotate. The surface of the housing is spray-coated and fully enclosed with seals to protect the slewing drive from contamination, damage and grease loss.

These components are assembled together to avoid customers installing various mating components, and we can also provide a variety of size standards.

The outstanding advantages of the slewing drive are as follows:

• The design is very compact, suitable for installation of mechanical equipment with limited space.

• Very high load carrying capacity in a very compact design.

• long lasting.

• Low maintenance costs.

• Cast housing protects internal parts.

Slewing drives are used worldwide for:

• Vehicle and crane systems.

• Rotation of attachments such as excavators, hydraulic tongs and forklifts.

• Facility management (automated systems).

• Loading and unloading equipment.

• Positioning Systems.

The rotary motion of the slewing drive is driven by a hydraulic motor or an electric motor. It is easy to find a matching hydraulic motor in the market, and it also conforms to industry standards, which can save a lot of time. For the motors, however, some device adapters are also required.

The housing of the slewing drive is a cast part and can be dimensioned according to customer requirements. The closed housing protects the swing system from contamination, damage and grease loss, ensuring smoother operation and longer life of the swing drive.

Additionally, labyrinth seals mounted on the housing structure protect the interior of the assembly from contamination if the swing drive is used in wet or dirty environments. Because the performance and reliability of the slewing drive depends to a large extent on the internal stability. It is worth noting that high-pressure water guns cannot be used to clean the swing drive, as the pressurized water will penetrate the seal and enter the inside of the swing drive, which will greatly reduce the service life.

Slewing drives can be used in temperatures ranging from -20°C to 70°C.

Proper and regular lubrication is required to ensure stable operation and long service life of the slewing drive. Grease is conducive to the better functioning of the rotary drive, reducing wear, reducing noise during operation, extending service life and reducing heat generation.

Periodically lubricate with a grease compatible with the seal material, depending on the frequency of use and ambient operating conditions.

It is best to fill the slewing drive with the same lubricating oil that was originally used. If you wish to use another type of grease, you must verify that the grease is compatible with the originally used grease. In addition, regular relubrication is recommended during operation and after extended periods of non-use or cleaning.

Grease that has been aged but not used should be replaced if it has not been used after three years. Also, greases must not be mixed with different thickeners and base oils.

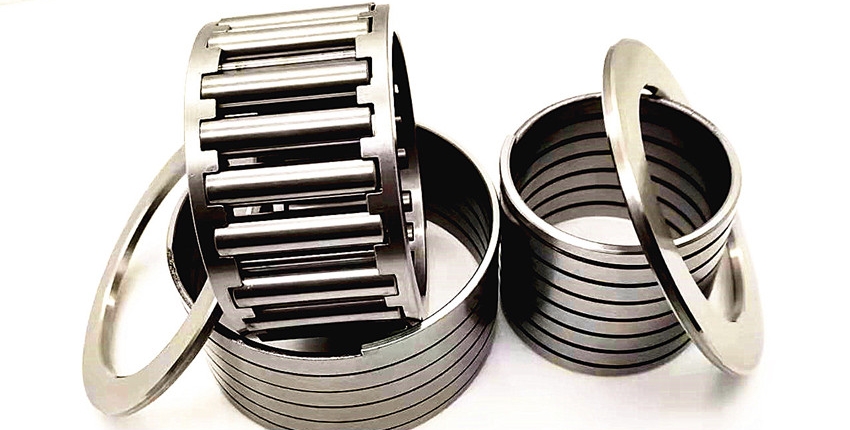

Flexible bearing/spring bush bearing used for continuous casting machines

The new produced flexible bearing/spring bush bearing are used for continuous casting machines for our Indian customer.

The flexible bearing/spring bush bearing with spring rings, made of special steel, it can be used in the condition of high temperature, dust contamination, heavy shock load, space limitations.

The life of the flexible bearing is very long compared with that of needle roller bearing, end user are re-using flexible bearing more than 3~4 times by cleaning and re-lubricating in maintenance period.

Also the flexible bearings are easy fitting and dismounting.

Split plummer block housing SNL3056G/SSNL3056G export to Europe

Split plummer block housing SSNL3056GG/SNL3056G

Split plummer block housing SSNL3056GG/SNL3056G

Bearing housings Split plummer block housings, SNL 30, 31 and 32 series Large SNL series for bearings on a cylindrical seat, with standard seals

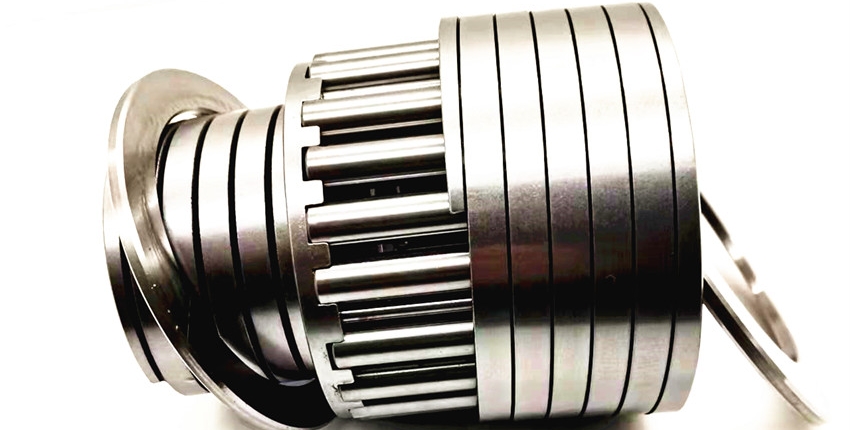

Combined roller bearing 4.063/400-0063 ready for delivery

Code: 4.063/400-0063

Description:

Combined roller bearing, a combined bearing is composed of three distinct components:

Radial Bearing: A profiled outer ring used for guided rolling contact along a steel rail or channel.

Axial Bearing: This integrated roller guides and maintains the position of the bearing along its track while offering axial load resistance.

Stub Axle (Shaft): This central shaft stabilizes the bearing and offers simple relubrication and assembly.

Industries:

Refuse, Automotive, Oil & Gas, Tool & Die Manufacturing, Medical, Packaging, Material Handling, Marine, Pulp and Paper, and General Manufacturing.

Applications:

Refuse trucks, forklifts, telehandlers, sorting and transfer systems, cranes and hoists, palletizers/depalletizers, high load lifts, cranes and hoists, horizontal and vertical feed units, shrink-wrappers, overhead conveyors, and automotive lifts.

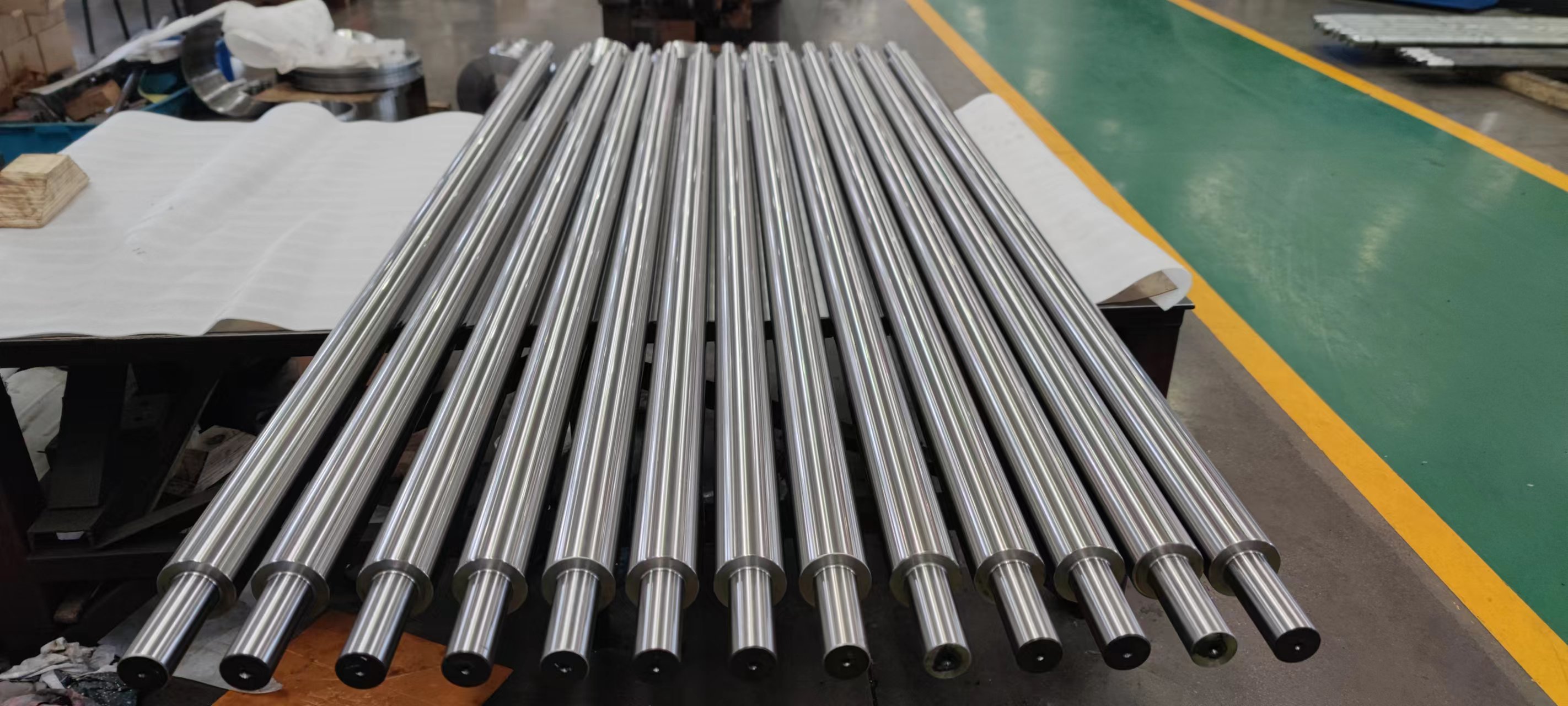

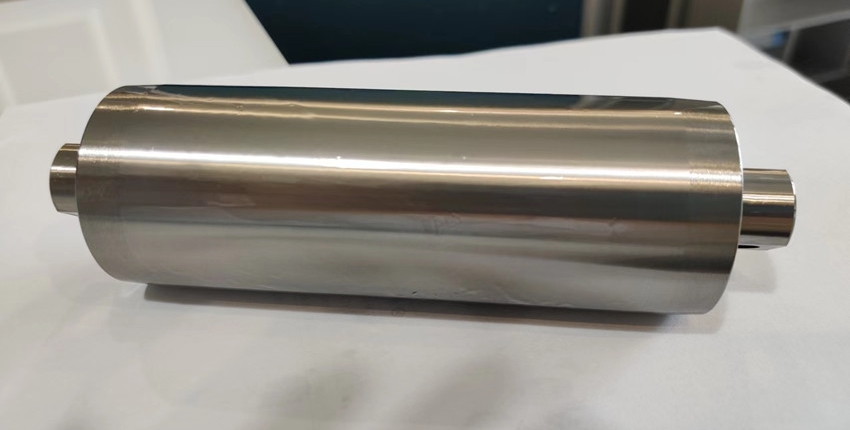

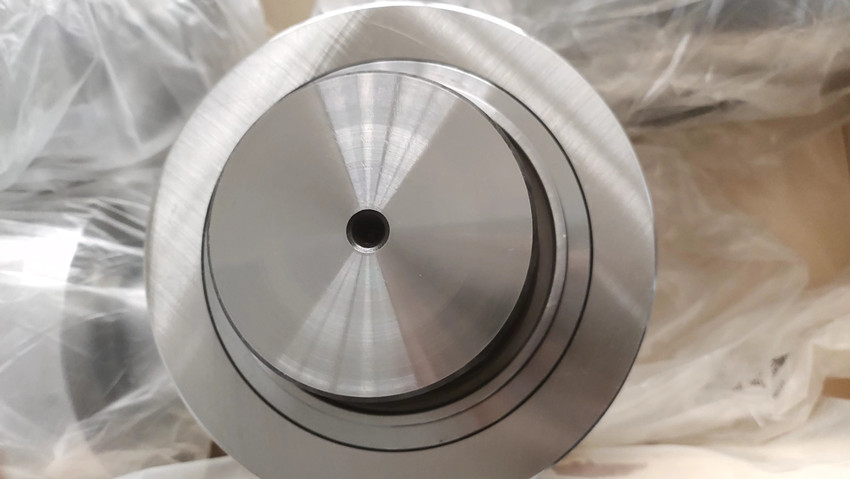

New finished back-up roller/backup bearing for our Italy customer

Code: BUR30X66X219

Description: Back up roller, backup roller, back-up roll, back-up roller bearing

Application: Metal sheet levelers, metal flattening machines, straightening machines

Dimension: Shaft diameter=30mm Outer diameter=66mm Shaft length=219mm

Material: Outer ring in GCr15 Shaft in GCr15

Hardness: 58~62 HRC

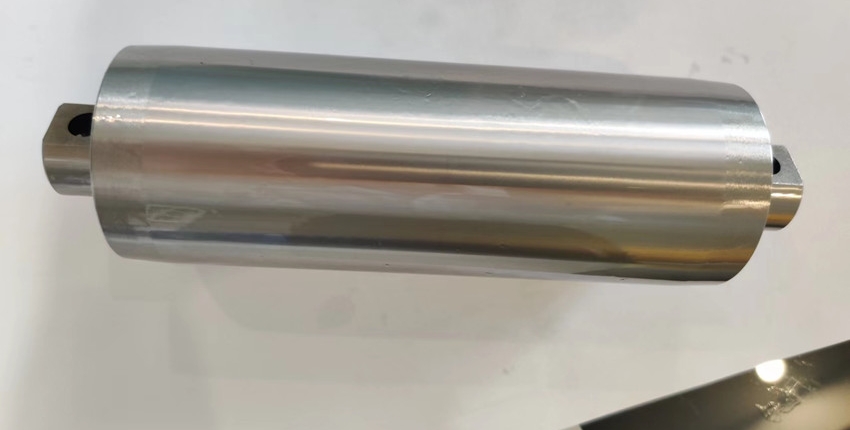

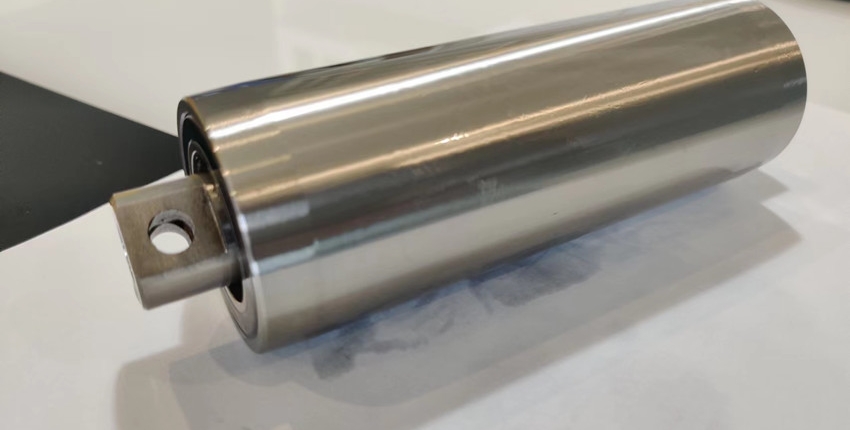

Back up roller BUR105X215X360 export to Turkey

Code: BUR105X215X360

Description: Back up roller, backup roller, back-up roll, back-up roller bearing

Application: Metal sheet levelers, metal flattening machines, straightening machines

Dimension: Shaft diameter=105mm Outer diameter=215mm Shaft length=360mm

Material: Outer ring in GCr15SiMn Shaft in 20CrMnTi

Hardness: 58~62 HRC

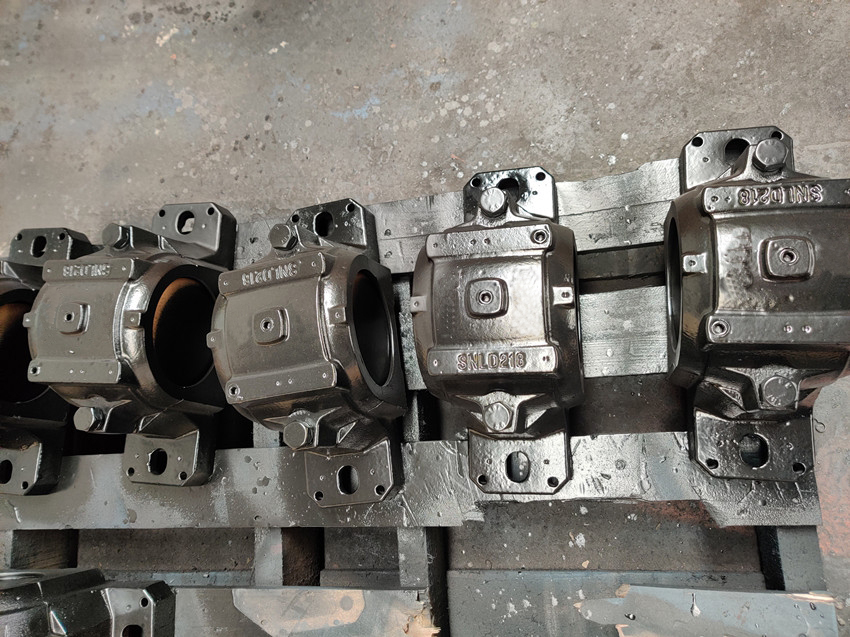

New finished plummer block housings SNLD218, SNLD528, SSNLD522-619 for our European customer

The new finished plummer block housings SNLD218, SNLD528, SSNLD522-619 are produced for our European customer, material in spheroidal graphite cast iron.

The upper cover and base of the split plummer block housing can be separated, mainly bear radial load. The housings are designed for the installation of self-aligning ball bearings or spherical roller bearings with adapter sleeve or cylindrical bore, mainly used in metallurgy, mining, conveying system, environmental protection equipment, etc.

LYSYM supply complete range of split bearing housings of SN200 series, SN500 series, SN600 series, SN300 series, SNU500 series, SNU600 series, SD3100 series, SAF500 series, 722500 series, 1500 series, SD500 series, SNL2,5,3,6 series, 1600 series, Z2500Y, Z2600Y series, GZ2, GZ4 series, the main difference between them is the different loads and different sealing forms (wool felt, double lip seal, U-seal, labyrinth seal, etc.). It has good thermal conductivity, easy installation and disassembly, and greatly improves the effectiveness of the seal.

Customized spiral roller bearing R75X150 ready for delivery

Spiral roller bearing R75X150

OD=75mm

H=150mm

The spiral roller bearing is assembled with elastic inner/outer rings and rollers, which enables it to work at 300℃. Its special structure ensures the constantly stable clearance, and supporting of radial shock load, while disables to limit the axial displacement of both bearing and its shell or bear the over-high axial load. Because of low limit speed, the bearing can bear 2° axial gradient of inner/outer ring in its installation and application.