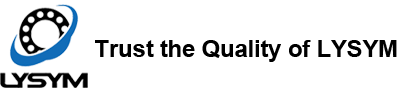

Rotary table bearing manufacturing process

Rough and finish turning by CNC lathes. Each process will be checked according to the drawings. Especially for the oil groove, ellipse, triangle, outer circle(ring) allowance, inner circle(ring) allowance, and chamfer must meet the requirements of the drawing. Well prepared for next steps.

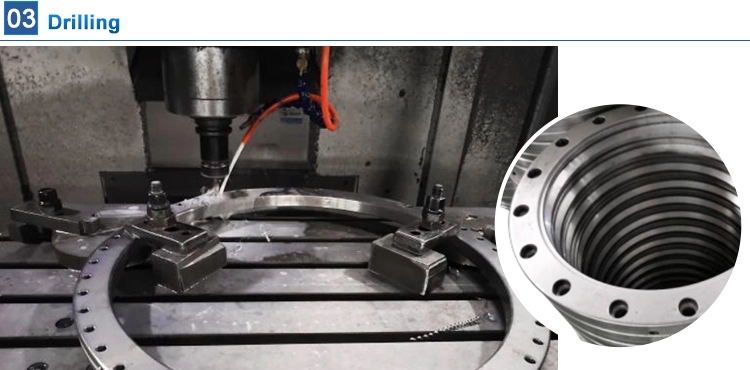

According to the drawings, the machining center is required to process. The key point is to level the countersink not to be uneven; the through hole be smooth without spirals; the threaded hole meets the requirements, can not drill bottom hole too large for easy & fast tapping. Hole chamfer requires angle, size and appearance all meet the requirements.

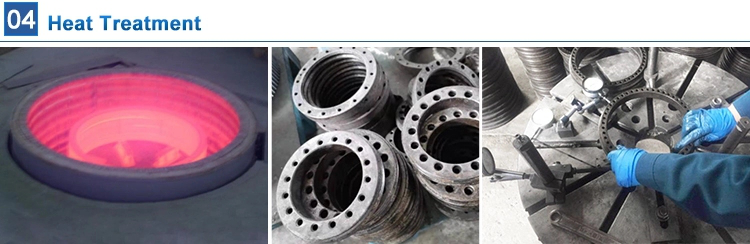

Heat treatment will be done according to the types of row material. Row material must ensure the hardness and heat treatment deformation are controlled within the qualified range.

A: Surface: Make sure that the machine is cooled in place, control the surface(plane)

bending and parallel difference(tolerance). Pickling flaw detection for the first product to see whether there is burning damage

or crack.

B: Outer diameter(ring): Control ellipse, triangle and size. When the product height is large, repeated grinding is needed .

C: Inner diameter(ring): Control ellipse, wall thickness and taper. If the product height is large, the vertical difference should meet the requirements.

D: Raceway: Due to the particularity of the product, it is necessary to grind at a fixed distance and ensure that the cooling is in place. The flaw detection of wall thickness for the sample should be qualified not less than 80%.

Ensure chamfer, oil groove smooth and without vibration.

100% finish grinding the surface, inner diameter and raceway. The key function is to improve the products’ accuracy, eliminate the ellipse and triangle deformation because of the tempering.

All procedures should be processed strictly in accordance with the drawings. Special for the temperature difference during tempering; roughness and angle during raceway processing for outer&inner diameter should be 100% inspected.

![]()

Magnetic Particle Inspection: fully magnetizing to make the magnetic powder evenly poured on the product. Observing whether the magnetic powder is concentrated. There would be no concentrated or remaining magnetic powder for good products.

Spring bush bearings with phosphatized coating

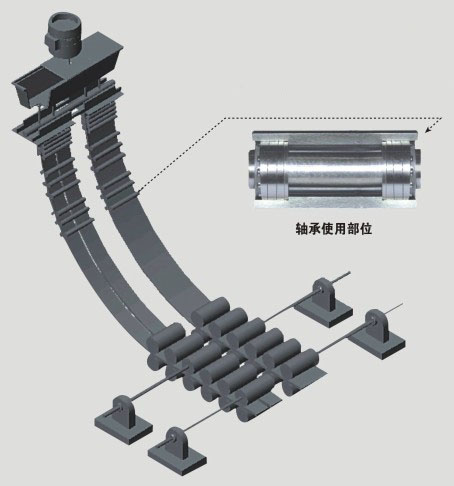

The spiral ring roller bearings produced by our Company are applicable in the high-temperature working area. When its temperature reaches 300, the bearing can still bear shock vibration load, ensuring the operation accuracy of the equipment.

Working conditions of the bearing dedicated to continuous casting machine:

High temperature – thermal radiation temperature in casting blank.

Shock – shock vibration load incurred in jiggering blank.

Dust – metal oxide producing in cooling cast blank.

Waste water – flow and high-temperature steam of cooling water.

Spiral Ring Roller Bearings

The inner/outer rings and rolling elements of these bearings may be fabricated to elastomers according to the working conditions, which accordingly saves space occupation of bearings significantly and facilitates easy assembly/disassembly.

Performance features:

1.The axial stretch of inner/outer ring and rolling element under high-temperature environment enables automatic compensation of radial internal clearance, which tackles the tough task of locking bearing when the rigid bearing encounters narrowed clearance at high temperature.

2.Satisfactory lubrication performance: The proper gap among the components and arrangement mode of rolling elements contribute to the continuous and even distribution of lubricating oil on the working surfaces.

3.Strong impact toughness: The components feature good elastic deformation absorbing shock wave energy sufficiently, which not only maintains stable precision of bearing, but also protects the equipment.